Design LCR Trigger for spark gap switch

2014年3月5日星期三

Explainations

Our group have finish all the part of designing and building works. However, our tutor hasn't do the experiment and get the results. Therefore, in week 5 our group just write the report and prepare for the bench day. These things would not showed on the blog any more.

2014年2月23日星期日

Week 4

In this week,we complete the renderings.

In addition,our group get the materials which have been processed.We pick up the completed materials from workshop and start to solder all the parts of materials to build the circuit.We order two standard copper wires,buy rubberized fabric to cover the wires to separate from other wires. Then we design the LCR circuit and connect the circuit using by welding technique. In this stage, we determine that the number of inductance turns is 500.Then we start to roll the coil on the PTFE bar (take lots of time). In soldering part, we found a big problem taht the Aluminium is hard to be soldered. After discussing, our group decide to use the Copper wires instead of Aluminium which could play a role in fixing.Finally, we complete all the circuit works and get the LCR trigger for spark gap switch which shows in the following.

In addition,our group get the materials which have been processed.We pick up the completed materials from workshop and start to solder all the parts of materials to build the circuit.We order two standard copper wires,buy rubberized fabric to cover the wires to separate from other wires. Then we design the LCR circuit and connect the circuit using by welding technique. In this stage, we determine that the number of inductance turns is 500.Then we start to roll the coil on the PTFE bar (take lots of time). In soldering part, we found a big problem taht the Aluminium is hard to be soldered. After discussing, our group decide to use the Copper wires instead of Aluminium which could play a role in fixing.Finally, we complete all the circuit works and get the LCR trigger for spark gap switch which shows in the following.

2014年2月13日星期四

Week 3

Our team just complete the final assembly view of 2-stage park gap switch today, which consist of 3 AL slices, one PTFE stick, two PTFE cubes and a holder.

In this week,our group complete all the engineering drawings of the spark gap switch and submit them to the workshop for processing. However,Due to machining problems, materials would be processed at week 5. Therefore, our group decide to complete remaining works together (write report, read reference articles and build up the circuit).

In the following, you can find our final engineering drawings.

|

2014年2月5日星期三

modification of design

After meeting our tutor, we make some modifications about our drawing design. You can see them in the following.However,we meet some problems in this section.We don’t know the value of inductance so it is hard to simulate circuit on Pspice. It is a hard work to read all the reference articles even if each group member read different articles at the same time.In addtion,Relevant data is hard to calculate before we read reference articles. Therefore, we just use estimated value to determine all the components’ parameters.

|

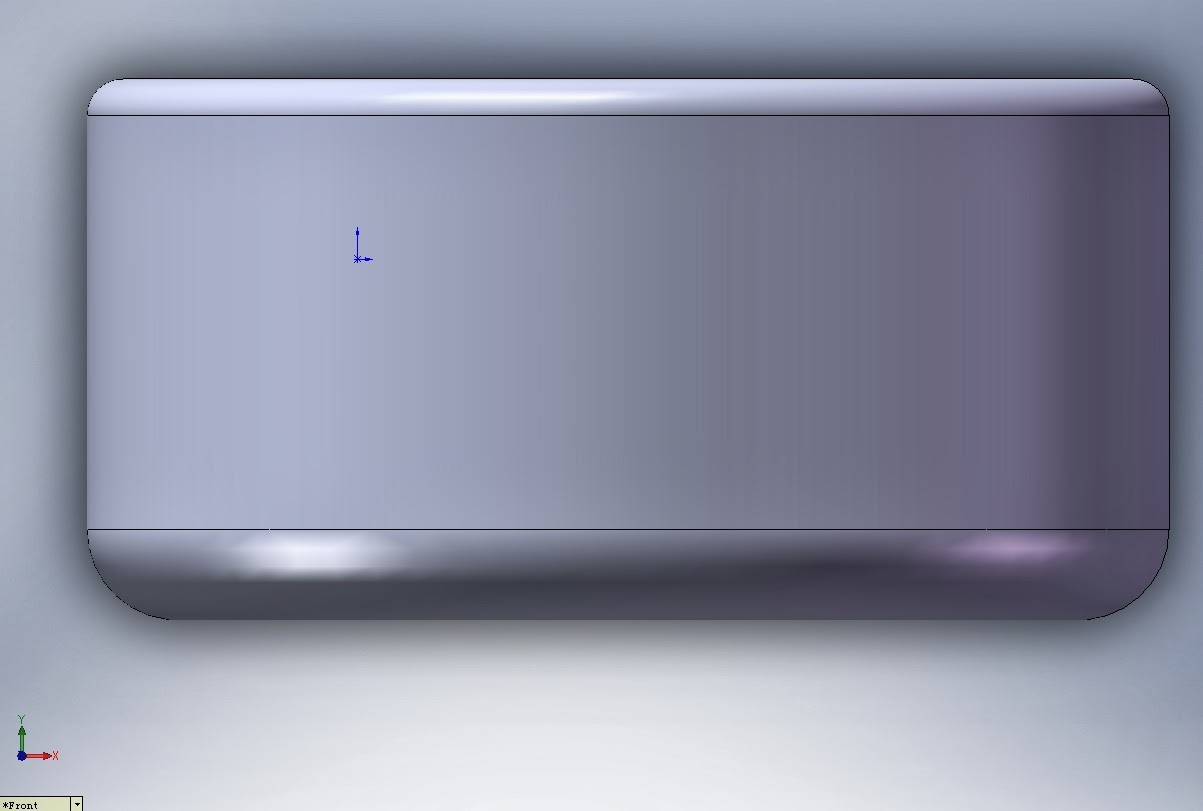

| PTFE-bottom effect picture |

|

| PTFE-top effect picture |

|

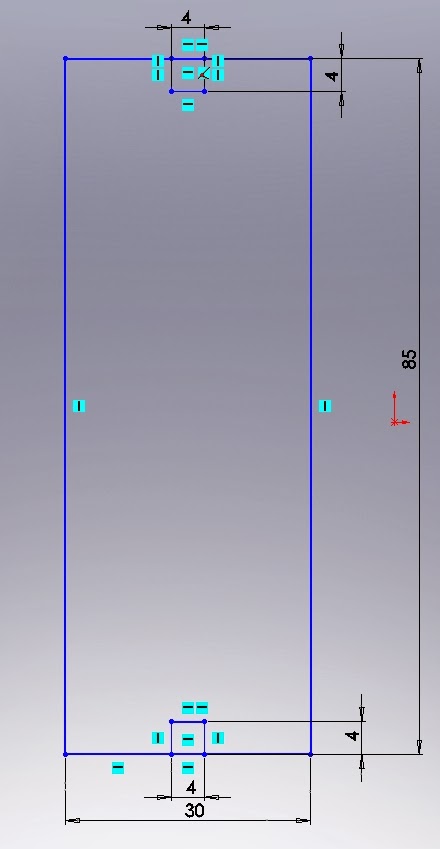

| PTFE-front and left view |

|

| PTFE-top and bottom view |

|

| sides AL-bottom effect picture |

|

| sides AL-bottom view |

|

| sides AL-construction |

|

| sides AL-front view+hole |

|

| sides AL-left view |

|

| sides AL-top effect picture |

|

| sides AL-top view |

|

| mid AL-bottom and top effect picture |

|

| mid AL-construction |

|

| mid AL-front view |

|

| mid AL-left view |

|

| mid AL-top view |

2014年2月2日星期日

Second week

In the second week, our group members seek advice from PhD Yuxuan Zeng and learn that how to make a design drawing by using Solid Works software.After hardworking, we complete the design three-view drawing of an LCR triggered 2-stage spark gap switch. In the following, I will show our drawing of spark gap switch.

|

| Middle AL custom view |

|

| Middle AL top view |

|

| Middle AL front view |

|

| It is the middle AL spin view. If we spin it along the central axis, we will get the overall view of the middle AL slice. |

|

| Top and bottom AL custom view-1 |

|

| Top and bottom al custom view-2 |

|

| Top and bottom al front view |

|

| Top and bottom al top view |

|

| Top and bottom al bottom view |

|

| Top and bottom al front view |

|

| PTFE custom view |

|

| PTFE front view |

|

| PTFE isometric view |

|

| PTFE top view |

Background

Group 48 students build this blog for the Year2 Project. Our group members are Gang Xu, Youjie Zhou, Wenbo Zuo and Peng Yuan. We choose ' Design LCR Trigger for spark gap switch' for our project.

The breakdown in a spark gap switch is a random event. In this project, the core problem is improving the breakdown chance. Therefore, an LCR trigger can be used with a multi-stage spark gap switch. We need to understand how LCR trigger works and build an LCR triggered 2-stage spark gap switch, which should has a 95% chance to breakdown when voltage reaches 7 kV.

In addition, in the last week of semester 1, we just submit the Components Ordering Form and other forms we need to complete. Our tutor was busy, so his PhD student Yuxuan Zeng has a meeting with us and gives some guidance to us, which helps us understand how LCR trigger works.

The breakdown in a spark gap switch is a random event. In this project, the core problem is improving the breakdown chance. Therefore, an LCR trigger can be used with a multi-stage spark gap switch. We need to understand how LCR trigger works and build an LCR triggered 2-stage spark gap switch, which should has a 95% chance to breakdown when voltage reaches 7 kV.

In addition, in the last week of semester 1, we just submit the Components Ordering Form and other forms we need to complete. Our tutor was busy, so his PhD student Yuxuan Zeng has a meeting with us and gives some guidance to us, which helps us understand how LCR trigger works.

订阅:

评论 (Atom)